Molecular modeling of high-performance polyamides

Polythiophenes and the power of Molecular Operating Environment

Prateek Verma / 01 November 2008

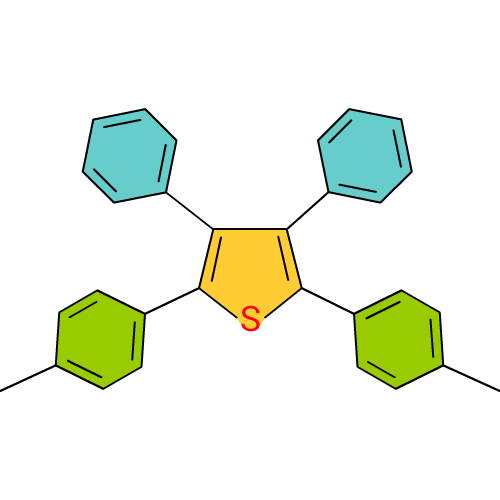

We know about how things melt; heating does the trick. But plastics undergo an additional transition - from a glassy to a rubbery state before they melt, at a temperature lower than its melting point. If you frequently go down the rabbit-hole of science videos on YouTube, you might have seen someone take a rubber ball and put it in liquid nitrogen for a minute. And then take out the ball and drop it on the floor - it shatters like glass. That's because rubber, which is polymeric, goes into a glassy state at a low enough temperature. Different plastics/polymers have different glass transition temperatures depending upon their molecular structure. I worked on computer simulations of molecular models of tetraphenyl-thiophene based polyamides. Polyamides are polymers like Nylon and Kevlar. Using computer simulations, one can tailor the molecular structure and predict polymer properties without needing to synthesize the polymer in laboratory. One use of these polymers was in coating applications in high-temperature scenarios due to their high glass-transition temperature. Simulations provided better understanding of the affect of side-groups and the replacement of amide group with imide group on the thermo-mechanical properties of these polymers.

Molecular Operating Environment (MOE) by CompChem was a fantastic molecular modeling environment software to work with. I personally loved it more than Accelrys Materials Studio at that time. or having to code from scratch. MOE supported a range of forcefields, energy minimization techniques in-built, an awesome structure creator, powerful molecular database management, and impeccable molecular viewers. I was helped by Dr. Y. S. Negi and the fantastic researchers at the Computational Chemistry lab at IIT Roorkee.

Last updated on April 11, 2022

This work was done in full or part at Indian Institute of Technology Roorkee.